Chapter 5 of “Managerial Accounting: An Introduction to Concepts, Methods, and Uses” focuses on the understanding of cost behavior and various methods for estimating costs. These concepts are essential for managers to predict how costs will change with different levels of activity, which is crucial for budgeting, planning, and decision-making.

Key Topics in Chapter 5

- Cost Behavior:

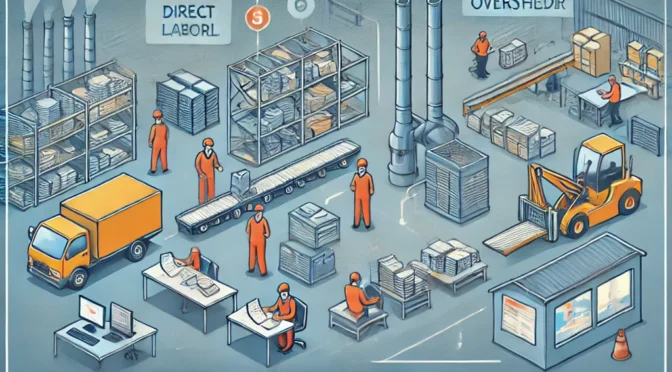

- Variable Costs: Costs that vary directly with the level of activity (e.g., raw materials). As activity increases, total variable costs increase proportionally, but the cost per unit remains constant.

- Fixed Costs: Costs that remain constant in total regardless of changes in the level of activity within the relevant range (e.g., rent). The cost per unit decreases as activity increases.

- Mixed Costs: Costs that contain both variable and fixed cost elements (e.g., utility bills with a fixed base charge plus a variable charge based on usage).

- Step Costs: Costs that remain fixed over a certain range of activity but jump to a higher level once the activity exceeds that range.

- Cost Estimation Methods:

- High-Low Method: A straightforward method used to separate the fixed and variable components of a mixed cost using the highest and lowest activity levels.

- Scatter Plot Method: Involves plotting all data points on a graph to visually assess the relationship between cost and activity.

- Regression Analysis: A statistical method that uses all data points to determine the line of best fit, providing a more accurate estimate of cost behavior.

- Relevant Range:

- The relevant range is the range of activity within which the assumptions about fixed and variable cost behavior are valid. Outside this range, fixed costs may change, or variable costs may not remain consistent per unit.

- Cost-Volume-Profit (CVP) Analysis:

- CVP analysis is a tool used to determine how changes in costs, sales volume, and prices affect a company’s profit. It is often used to calculate the break-even point or to assess the impact of different pricing strategies.

Math Problem and Solution from Chapter 5

To illustrate the High-Low Method for cost estimation, consider the following problem:

Problem:

A company, ABC Enterprises, has tracked its utility costs over several months and wants to estimate its future costs based on usage. The highest level of activity recorded was 2,000 machine hours with a cost of $15,000, and the lowest level was 1,200 machine hours with a cost of $10,200. Estimate the variable cost per machine hour and the fixed cost using the High-Low Method.

Solution:

- Calculate the Variable Cost per Machine Hour: The High-Low Method first determines the variable cost per unit by identifying the change in cost divided by the change in activity level. $$

\text{Variable Cost per Machine Hour} = \frac{\text{Cost at High Level of Activity} – \text{Cost at Low Level of Activity}}{\text{High Activity Level} – \text{Low Activity Level}}

$$ Substituting the values: $$

\text{Variable Cost per Machine Hour} = \frac{15,000 – 10,200}{2,000 – 1,200} = \frac{4,800}{800} = 6 \, \text{per machine hour}

$$ - Calculate the Total Fixed Cost: After determining the variable cost per unit, the fixed cost is calculated using the total cost equation at either the high or low activity level. $$

\text{Total Cost} = \text{Fixed Cost} + (\text{Variable Cost per Machine Hour} \times \text{Activity Level})

$$ Using the high level of activity: $$

15,000 = \text{Fixed Cost} + (6 \times 2,000)

$$ $$

15,000 = \text{Fixed Cost} + 12,000

$$ Solving for the Fixed Cost: $$

\text{Fixed Cost} = 15,000 – 12,000 = 3,000

$$ - Total Cost Equation: Now, the total cost equation based on the High-Low Method can be expressed as: $$

\text{Total Cost} = 3,000 + 6 \times \text{Machine Hours}

$$ This equation can be used to estimate future utility costs based on the expected machine hours within the relevant range.

Conclusion

Understanding cost behavior and accurately estimating costs are critical for effective managerial decision-making. The High-Low Method, as illustrated, is a simple yet effective tool for estimating the variable and fixed components of mixed costs, allowing managers to predict future costs and make informed decisions. By analyzing costs in this manner, managers can better control costs, plan budgets, and enhance profitability.